To save space, improve process and reduce maintenance in critical heat exchanger duties:

Challenge

Solution

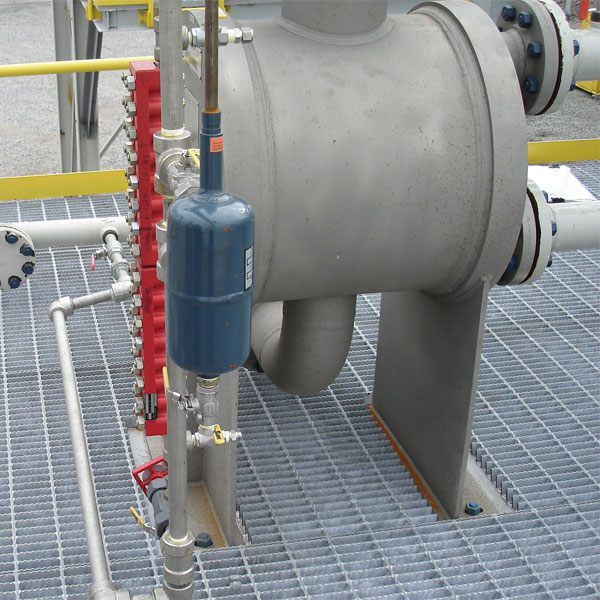

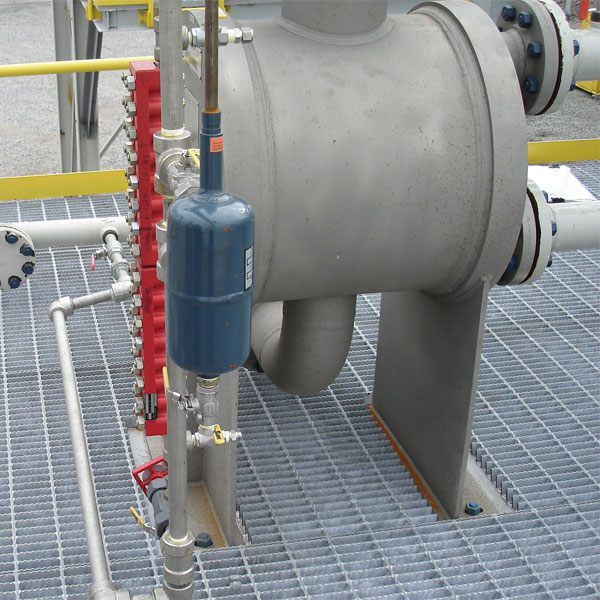

Tranter SUPERMAX® Shell & Plate Heat Exchangers in ammonia, nitric acid and urea manufacturing.

Results

Heat Exchanger Experts For Over 85 Years.

To save space, improve process and reduce maintenance in critical heat exchanger duties:

Tranter SUPERMAX® Shell & Plate Heat Exchangers in ammonia, nitric acid and urea manufacturing.