Category for the Roles Track

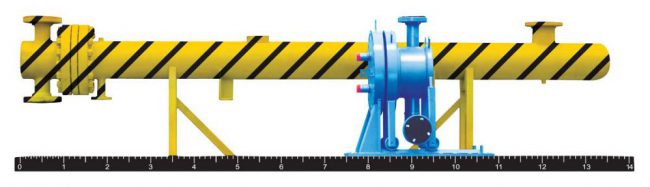

These two heat exchangers have equivalent duties. The blue one costs less, is easier to install, has a much smaller footprint, responds faster and is easier to clean. Which one should be a candidate for your next expansion or construction? Expansions of building envelopes or of process output is capital intensive, with large demands on…

It is important that your thermal systems respond quickly to control signals, which generally come from thermostats or building automation systems, or from process control systems. Responding slowly can affect your business many ways: Excessive energy consumption Uncomfortable indoor environment incidents that are slow to correct Under- or over-processed products Variable quality Fast-responding heat exchangers…

Your thermal systems, whether HVAC or process, produce a byproduct of low-grade, “waste” heat energy. If your engineers limit their thinking and options to shell and tube heat exchangers, they will view these waste heat streams as uneconomical to try to capture and recycle. That is because these old technology heat exchangers are too inefficient…

All heat exchangers transfer heat energy between two or more fluid media contained in channels. These channels scale or foul over time, accompanied by declining performance and higher fuel bills. If your facility uses old technology shell and tube heat exchangers, you will have higher fuel bills, plus a more frequent cleaning burden than with…

Many facilities have been built using shell and tube heat exchangers. When time for expansion comes, whether involving HVAC or process thermal systems, sizing and installing a larger shell and tube exchanger is expensive or impossible because the larger unit: Causes impossible-to-resolve piping conflicts with existing systems Exceeds the load capacity of support structures Has…

PLATECOIL heat recovery banks in wet gas and liquid streams cut industry fuel bills significantly. At the same time, they knock out troublesome vapor plumes and reduce thermal load on effluent plants. Wet flue gas streams as low as 67°C (150°F) are a candidate for big savings from PLATECOIL heating banks. From such a moist…

Whatever brands of plate heat exchangers are installed in your facility, they originally started up delivering OEM nameplate performance. Tranter Service Centers want to ensure that you continue to enjoy nameplate performance. Our fast, economical and reliable service means minimal downtime for your exchanger and reliable protection for your equipment. That’s why we offer OEM…

Clean heat exchange surfaces in both channels are critical for the controllability and energy efficiency of a heat exchanger. Fouled surfaces result in complaints from your employees. Typical problems include interior comfort complaints, off-grade product from lack of temperature control, excessive flash steam vapor, escalating utility bills and related troubles. Some problems are minor but…

Tranter can fabricate a plate pack with a larger number of plates throughout the range of plate diameters. Tranter offers its wide-gap, deep-draw plates throughout the range of sizes; others do not. Tranter uses plasma arc welding for perimeter and porthole welding. Others use a fusion weld that can be asymmetrical. Tranter uses all-metallic plate…

The SUPERMAX® Shell And Plate Heat Exchanger is worthy of consideration for all duties with fluctuating temperature and pressure vs. bloc-type units. The reason is that welded heat exchangers with square/rectangular plates (the four corner grid design) suffer from thermal and pressure fatigue due to the weak corner welds. These welds often fail in dynamic…