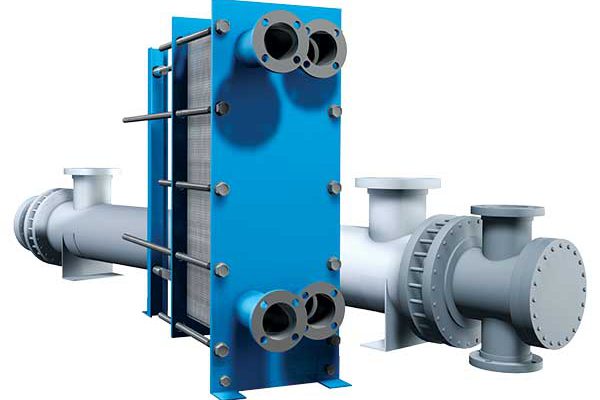

Your thermal systems, whether HVAC or process, produce a byproduct of low-grade, “waste” heat energy. If your engineers limit their thinking and options to shell and tube heat exchangers, they will view these waste heat streams as uneconomical to try to capture and recycle. That is because these old technology heat exchangers are too inefficient for these duties. They could only capture a tiny fraction of the heat that a plate heat exchanger could capture, making the shell and tube option wholly uneconomical. So, they are content with sending a lot of this low-grade energy to the sewer—along with the precious energy that it took to produce the heat in the first place. Also they would be content with asking you to supply additional energy to do what the recovered heat energy could do instead.

USEFUL ENERGY FROM STACKS, DRAINS, DUCTS

Tranter has a better way. Our PLATECOIL Prime Surface Heat Exchanger panels are configured into banks that capture low-grade heat energy from exhaust gas, from flash steam tanks, from drains—anywhere you have hot gases, vapors or liquids that are otherwise being disposed of. These banks can be installed in stacks, flues, pipes, drains and various other locations, recovering heat for productive use.

These recovery systems are relatively light and highly efficient at exchanging heat. At the same time, they are resistant to the fouling or plugging that plague finned-tube exchangers that are sometimes used.

LARGE SAVINGS, ATTRACTIVE RETURN

Look around your facility for signs of waste energy being disposed of without a second thought. The evidence is there: vapor plumes from tank vents, stacks or cooling ponds, troublesome cooling towers, hot dryer exhaust and so forth. Direct your technical staff to our heat recovery Application Data Sheets, and have them catalog the data on these streams and send them to Tranter. We’ll show you what kind of savings you can send straight to your bottom line, with an attractively short return on capital.