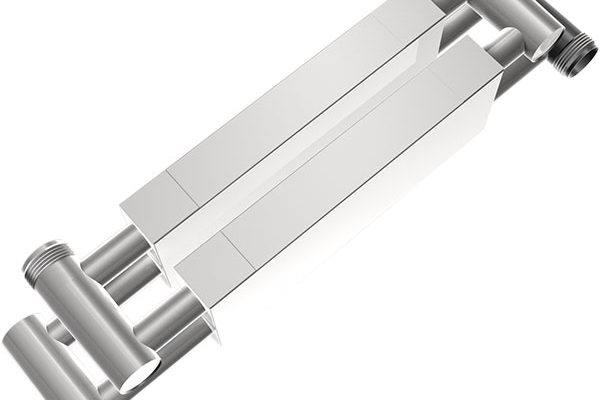

ThermoFit plate technology is a new Tranter design concept offering a significant boost in plate and frame heat exchanger performance and unit integrity. ThermoFit plates, available in both stainless steel and titanium alloys, feature three new design approaches:

- The HydroFit™ Flow Distribution System Concept

- The GrooveFit™ Groove/Gasket System Concept

- The Halo™ Plate Alignment Concept

The HydroFit™ concept achieves minimized plate width throughout the range to enhance flow distribution and hence heat exchange performance and also to reduce frame cost.

The simulation-tuned GrooveFit™ gasket and groove design features minimal wetted area of the gasket, for maximum fluid integrity over long service cycles.

The exclusive Halo™ plate alignment system with a plate-to-plate nesting feature establishes and maintains optimal plate alignment and gasket sealing integrity.

All Tranter SUPERCHANGER plates offer attractive advantages:

- Exclusive gasket/bleed port design prevents cross-contamination

- Fluids will not intermix

- The only means of intermixing can be a through-plate failure

- Liquid flowing on the surface of each plate flows on the inside of the boundary gasket

- In case of a leak beyond a boundary gasket, flow will only occur to the outside of the unit through the bleed ports

- Numerous gasket choices from among specially molded elastomers assure superior performance